Optimizing Palletization

Density based freight class is determined using the handling unit's dimensions and weight. When dealing with pallets, this gives you some control over freight class based on how the pallet is built. Using appropriately sized pallets, properly building pallets, combining or stacking pallets together, or even adding a bit of weight can all help reduce a handling unit's freight class, in turn, potentially reducing your costs.

Proper Pallet Sizing

Utilizing appropriately sized pallets for the product you are shipping is key to minimizing dimensions, and it turn, freight class. This box being shipped on a full sized pallet comes in at a dimensional freight class of 400. Using a partial pallet the size of the boxes length and width would reduce the dimensional freight classification to 70!

Stacking / Combining Pallets

Stacking or combining pallets is another method you can use to control dimensional freight classification. The pallets displayed below have freight classes of 100 and 110. However, by stacking the pallets together the dimensional freight class of the resulting pallet is only 100, which will generally result in a lower over all cost than the higher rated, seperate pallets.

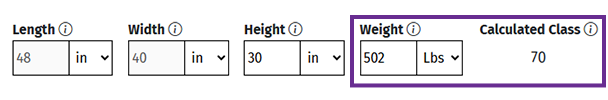

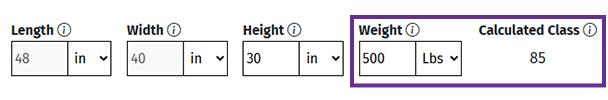

Adding Weight

Sometimes something as simple as adding a few pounds to a pallet can drop it to a lower dimensional freight classification, resulting in a lower rate for the handling unit. Generally, the heavier the pallet is to begin with, the more beneficial adding a few pounds to drop the freight class will be.

+2 LBS